Learn: What Is a Plow Plane? | Purpose, Benefits and Usage |

A plow plane is a traditional woodworking tool and a testament to the craftsmanship of centuries past. Its

roots date back to ancient times, and the plow plane has retained its relevance and utility in modern woodworking practices.

This specialized hand tool serves a crucial role in creating precise and controlled grooves, or “plows,” in wood. Woodworkers can create fashion joints, dadoes, and decorative elements with remarkable accuracy.

In this article, I will describe the essence of the plow plane, its history, components, functions, and the importance of its holds in the field of woodworking.

So, stay with me to understand what is a plow plane.

What is a Plow Plane? (Definition)

A plow plane is a woodworking hand tool used to cut grooves (or “plows”) in wood, enabling precise creation of joints, dadoes, and decorative elements with controlled depth and accuracy.

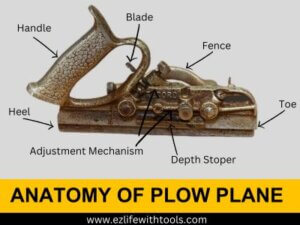

Anatomy of a Plow Plane

A plow plane consists of several essential components that work to facilitate creating precise groves in woodworking tasks. It is necessary to understand its anatomy to be an expert.

Stock:

The stock forms the body of the plow plane, providing the structure and stability for the tool. Typically made from wood or metal, the stock houses the blade and other vital elements.

Blade:

In the center of the plow plane lies the blade for cutting grooves into the wood. The sharpness, angle, and adjustment of the blade ensure the accuracy and depth of the cuts.

Fence:

It is responsible for straight and consistent cuts and works as a guide. It runs parallel to the wood’s edge and aids in maintaining precision while using the plow plane.

Depth Stop:

This adjustable feature determines the depth of the cut. By setting the depth stop, woodworkers can achieve uniformity in the groove or rabbet depth.

Adjustment Mechanism:

The plow plane has different knobs, screws, or levers, which facilitate to adjustment of the blade’s position and angle and enable fine-tuning for optimal cutting performance.

Handle or Knob:

It is a simple handle or knob attached to the main body of the plane to provide a comfortable and secure hold to you while maneuvering the tool.

Toe and Heel:

The plane front part consists of the toe, and the back is the heel. These sections help provide stability and support when applying pressure during use.

Types of Plow Planes

Plow planes have evolved over time, resulting in various types distinguished by their construction, materials, and functionality, catering to different woodworking preferences and needs. You can categorize them into two parts.

- Traditional Handheld Plow Planes

- Modern Plow Planes

1- Traditional Handheld Plow Planes

Wooden Plow Planes

The wooden plow plane is the iconic symbol of traditional woodworking craftsmanship. It was made from hardwoods like beech-maple or rosewood. This hand tool has a timeless design that has endured for centuries.

Its wooden body shows skilled craftsmanship. Its fence part is usually made of brass or wood attached firmly to the body to guide the precise path of the blade.

A well-crafted wooden plow plane not only serves as a functional tool but also as a testament to the artistry and precision achievable with natural materials.

Woodworkers appreciate its elegant simplicity and the tactile connection it offers, allowing for a more intimate and nuanced control over the tool.

Despite the availability of modern metal counterparts, the wooden plow plane continues to hold a special place in the hearts of artisans, embodying a blend of functionality, tradition, and aesthetic appeal.

Metal Plow Planes

The metal plow plane is also essential due to its durability. It is made of robust materials like cast iron or steel and has exceptional strength and resilience. It has a strong body and adjustable design, which can bear any rough use.

Its fence part is usually adjustable and machined to provide stability and accuracy. The components of metal plow planes are created complicated to provide precise adjustments with screws, knobs, or levers to control blade depth and alignment.

Woodworkers appreciate the durability of the metal plow plane, as it offers consistent performance and ease of maintenance.

2- Modern Plow Planes

You can categories them into two for better understanding.

Power Plow Planes

Incorporating electric or pneumatic mechanisms in power plow planes enhances efficiency by automating some of the cutting processes. These motorized versions offer increased speed and consistency in cutting grooves, catering to larger-scale woodworking projects.

Adjustable Plow Planes

Adjustable plow planes allow woodworkers to make quick and precise adjustments to accommodate various groove widths and depths. They often feature mechanisms for easy blade changes and adjustments, offering convenience without compromising accuracy.

Purpose and Uses of a Plow Plane

A plow plane serves as a versatile woodworking tool, offering a range of applications that contribute to the precision and finesse of crafted wood pieces.

Groove Cutting

The primary purpose of a plow plane is cutting grooves along the grain of the wood for housing panels, creating joints, or accommodating sliding doors.

Joinery Work

Plow planes excel in creating joints like dadoes and rabbets. When you develop shelves, partitions, drawers, or door panels, it helps to create dado and rabbet joints to fit all the pieces of wood together. It is necessary to use it along the grain direction. The joints created by the plow plane are strong, durable, and seamless.

How to Use a Plow Plane

Mastering the use of a plow plane requires understanding its setup, adjustments, and various techniques that contribute to precise woodworking.

- Setup and Adjustment

- Techniques for Effective Usage

1- Setup and Adjustment

Blade Installation

First, install the blade securely into the plow plane and ensure that it is properly seated and aligned. It is a crucial part of any plane. So, adjust the blade’s position according to the desired groove width and depth.

Fence Setting

Place the fence parallel to the edge of the wood piece to guide the plow plane and maintain straight cuts. Ensure the fence is securely locked in place to prevent deviation during operation.

Adjustment of Depth Stop

Adjust the depth stop to control the depth of the cut. This adjustment determines how deep the plow plane cut into the wood and ensures uniformity across the project.

2- Techniques for Effective Usage

Dados Creation

To cut dadoes across the wood grain, position the fence accordingly and adjust the depth stop to achieve the desired depth. Continue the procedure with controlled passes to ensure uniformity across the dado.

Grooves Cutting

Hold the plow plane firmly against the wood surface and start cutting the groove. Push the plow plane along the intended path, applying consistent pressure. Check the depth and width frequently to ensure the accuracy.

Rabbets Creation

Adjust the plow plane to the desired depth and set the fence for cutting along the wood edge. Push the plane along the wood surface to create a rabbet and ensure precision and smoothness.

Advantages of Plow Planes

The plow plane has many distinctive advantages that set it apart from other woodworking tools. Here are some of them.

- Plow planes offer a quieter, more hands-on approach than routers.

- Woodworkers have greater control over the depth and width of cuts.

- It can create precise and customized grooves or joints.

- It is suitable for various wood types and project sizes.

Maintenance and Caring Tips

Maintenance of the plow plane not only ensures its longevity and optimal performance but also achieves accurate and clean cuts. Several vital steps are involved to preserve the tool’s functionality.

- Sharp the blade regularly using a honing stone.

- Monitor the blade’s condition to check the signs of damage. If the blade becomes excessively dull or damaged despite sharpening, consider replacing it to maintain optimal cutting performance.

- After each use, clean the plow plane to remove the wood shavings and dust with the help of a brush or compressed air.

- Apply a light coat of any lubricant or oil to the metal parts of the plow plane to prevent rust and corrosion.

- Cover it with a protective case and store it in a dry and clean environment to prevent moisture buildup and potential damage.

Conclusion

Throughout history, artisans have relied on the plow plane to achieve impeccable joints, precise grooves, and seamless woodworking projects.

From traditional handcrafted wooden planes to modern iterations boasting motorized mechanisms and adjustable features, the plow plane has adapted to meet the ever-evolving demands of woodworking practices.

Whether cutting grooves, creating dadoes, or forming rabbets, the plow plane empowers woodworkers to bring their woodworking visions to life with finesse and accuracy. As woodworking practices advance, the plow plane remains an essential tool.

I am confident that you enjoyed the discussion about the plow planes.

Thank you for your time.

Best wishes

Frequently Asked Questions

What is the anatomy of a plow plane?

A plow plane consists of several essential components that work to facilitate creating precise groves in woodworking tasks. It is necessary to understand its anatomy to be an expert.

1- Stock

2- Blade

3- Fence

4- Depth Stop

5- Adjustment Mechanism

6- Handle or Knob

7- Toe and Heel

What is the difference between a plow plane and a combination plane?

A plow plane only used for cutting grooves or dadoes, and combination plane can create dados, rabbets, and molding profiles by changing its attachments.

What is the purpose of a plow plane?

A plow plane serves as a versatile woodworking tool, offering a range of applications that contribute to the precision and finesse of crafted wood pieces.

1- Groove Cutting

2- Joinery Work