How to Prevent Plywood from Warping: Proven Methods

You know very well about the common building material, which is plywood. It is the most used product in the

external and internal walls and furniture of the house.

It consists of different thin wood layers. It has multiple benefits and only one drawback: it can be warped due to some reason.

Warping in plywood can be a frustrating issue, causing structural flaws and impacting the quality of your projects. Understanding its causes and implementing effective prevention measures are necessary to ensure the longevity and durability of plywood.

In this article, we’ll delve into the core reasons behind plywood warping, explore essential preventive steps, and equip you with practical techniques to safeguard against this common concern.

So, keep reading.

What is Warping?

When deformation occurs in the plywood shape due to the fluctuation of moisture content at the different parts of the wood piece, it is called warping.

Causes of Plywood Warping

Plywood warping occurs due to various factors that affect its structural integrity. Here’s a detail of these causes:

Effect of Moisture Content:

Due to the multiple thin layers of plywood, it is a very sensitive material to moisture, especially when it is placed in an open space or humid environment.

Therefore, fluctuations in moisture levels can cause wood fibers to expand or contract, and plywood will be warped. The big reason behind warping is moisture fluctuation.

Methods of Storage and Their Role:

Improper storage is a significant cause of plywood warping. Storing plywood in areas with high humidity or direct exposure to sunlight can cause uneven moisture.

Incorrect stacking or laying plywood flat on uneven surfaces during storage can also cause warping.

Therefore, always ensure that plywood is stored in a dry, well-ventilated area, and the place should be flat with adequate support.

Effect of Loading and Quality:

Uneven loading or stress on plywood surfaces can induce warping. Placing heavy objects on one side or applying uneven pressure can cause deformation.

Additionally, the quality of plywood is crucial to check before constructing any project because quality plays a crucial role.

Lower-quality plywood, with inconsistencies in wood density or adhesive application, is more prone to warping under stress or moisture changes.

Wood Warping Varieties and Their Causes

Different wood species have different levels of susceptibility to warping. Some of them are more sensitive to warping due to their inherent characteristics, density, or grain patterns.

Understanding the types of wood warping and their causes is crucial for effectively preventing plywood issues.

Here’s detailed information on the different types of wood warping and their associated factors for you.

Behind warping, these 5 types are included.

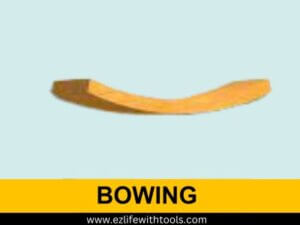

- Bowing

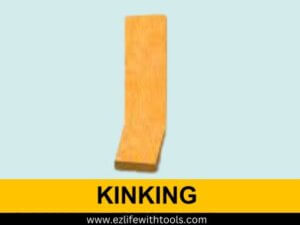

- Kinking

- Twist/Wind

- Cupping

- Crooking

1- Bowing

Bowing in plywood is the curved deformation along its length caused by moisture changes or stress, impacting its flatness and structural integrity.

Cause: It occurs when there is a curvature along the length of the plywood sheet. Often, it happens due to uneven moisture, where one side absorbs moisture more rapidly than the other, causing the wood to bend.

2- Kinking

The sharp bends in plywood, which affect its usability and structural stability, are called kinking.

Cause: The main reason behind this is often external stress, such as improper handling or storage, leading to a sudden, distinct bend in the wood.

3- Twist/Wind

Rotational deformation at one or both ends of the plywood is called twist/wind.

Cause: It can be due to uneven drying, losing moisture faster at one end than another, or manufacturing fault.

4- Cupping

It appears as a concave or convex distortion along the width of the plywood sheet.

Cause: The main cause behind it is the absorption of moisture on opposite edges of the plywood, which results in curling on the edges of the plywood.

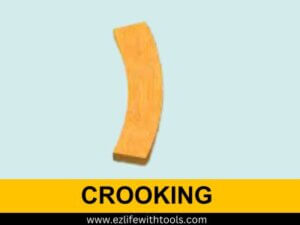

5- Crooking

Deviation of straightness in plywood along the length is called crooking.

Cause: Uneven drying or moisture absorption leads to this form of warping.

Importance of Preventing Plywood Warping

Preventing plywood warping is important to ensure its durability and structural integrity. Here, I have described in detail why it’s important to address this issue:

Structural Integrity:

Warping affects the structural stability, load-bearing capacity and overall strength of plywood.

Because a warped piece of plywood may not fit properly in construction, creating gaps, misalignments, or weakened joints.

Warping also creates safety hazards and destroys the quality of the final product.

Aesthetic Appeal:

Warped plywood affects the aesthetics of finished projects. It distorts the surfaces, which causes irregularities and unevenness to the visual appeal of furniture, cabinets, or any woodworking creation.

Longevity and Functionality:

Plywood warping significantly reduces the durability of wood-based products because warped surfaces are an open invitation to further damage, especially when it is subjected to stress or load-bearing activities.

Preventing warping ensures the longevity and functionality of plywood-based items and maintains their usefulness over time.

Cost Efficiency:

It is a common thing that preventing plywood warping is more cost-effective than resolving warped issues.

Repairing or replacing warped plywood will require a huge amount of precious time and money.

So, applying preventive measures saves both time and money to avoid the need for costly replacements or repairs.

How to Prevent Plywood from Warping Using Different Techniques

Preventing plywood warping requires targeted strategies designed specifically for this versatile material. These are the specialized preventive measures:

Minimize Internal Stress:

One of the effective ways to prevent warping in plywood is to use the right cutting technique. Because it can help you to minimize the internal stresses in the wood, if you have succeeded in reducing the internal stress, it will automatically prevent the warping.

So, always follow the sawing techniques that follow the wood’s natural lines to reduce the tension within the lumber.

Addressing Moisture Concerns:

Apply moisture-resistant coatings or sealants to plywood surfaces. These barriers protect against moisture absorption, a primary cause of plywood warping.

Seal the edges of plywood sheets thoroughly with appropriate sealants to prevent moisture ingress, especially along the vulnerable end grain.

Proper Storage Practices:

Store plywood flat and adequately supported to avoid sagging or bending.

Keep sheets off the ground and ensure even support across their entire surface to prevent warping.

Always store plywood in well-ventilated areas with controlled humidity to maintain consistent moisture levels.

Sealant Application:

Pay special attention to sealing the end grain of plywood sheets. This vulnerable area absorbs moisture more readily, making proper sealing crucial in preventing warping.

Handling and Transportation:

Handle plywood sheets carefully during transportation and construction to avoid bending or stress that could induce warping.

Quality Adherence:

Utilize high-quality plywood with consistent thickness and superior adhesion between layers. Quality materials are less susceptible to warping.

Importance of Using Moisture Meter and Anti-Warping Agents

Role of Moisture Meters:

It is a small-sized meter that looks like other meters. The main purpose of this meter is to monitor the moisture content in the atmosphere.

If you use it properly, these meters provide precise readings of plywood’s moisture content. Then, you can maintain the appropriate moisture level to prevent the warping and be aware of potential warping issues before they escalate. So, regular monitoring will save your precious plywood.

Role of Anti-Warping Agents:

When you apply the anti-warping agent, like sealant, on the plywood surface, they create a protective barrier against moisture absorption. Which significantly reduces the risk of warping caused by environmental moisture fluctuations.

These anti-warping agents also enhance plywood stability by reducing the impact of external factors like temperature changes or humidity variations, thereby preserving the integrity of the material.

Conclusion

Preventing plywood warping is a critical aspect of successful woodworking endeavors.

Understanding the causes and implementing targeted preventive measures is necessary to maintain the structural integrity of plywood.

By addressing moisture concerns, utilizing appropriate tools like moisture meters and anti-warping agents, and adhering to best practices throughout handling, storage, and construction, you can significantly minimize the risk of warping.

These strategies not only ensure the longevity and durability of plywood-based projects but also their standards.

I am confident that after reading this article, you do not have any queries in your mind about how to prevent plywood from warping.

It is an honor for me that you solved an issue with the help of my article.

I always share a comprehensive guide related to all aspects of your queries.

Thank you for your time.

Best wishes

Frequently Asked Questions

Can you flatten plywood with weight?

Yes, you can flatten plywood using weight. One common method is to place heavy objects on top of the plywood sheet and leave them there for a period of time.

Does oiling wood prevent warping?

Yes, it can help to prevent warping but not a foolproof solution. Oiling helps in moisture regulation, stability and surface protection.

How do you flatten wet plywood?

There is a simple process to flatten wet plywood. Follow these steps.

1- Allow Drying

2- Weighted Pressure

3- Even Distribution

4- Time

5- Flip and Repeat

6- Stabilize