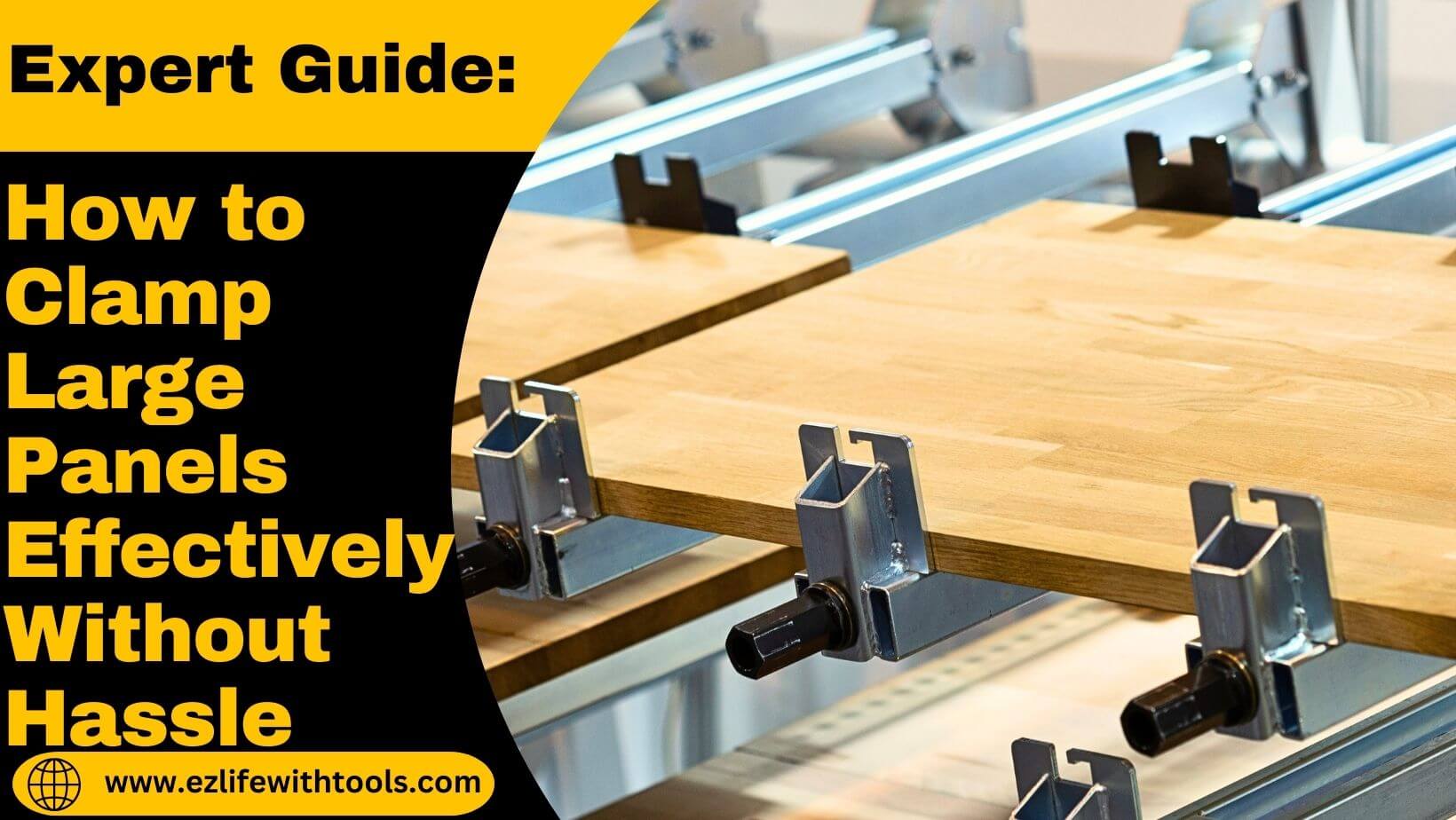

How to Clamp Large Panels Effectively Without Hassle

Whether you are assembling furniture or building structural elements, it is necessary to clamp it first because

the stability and accuracy of any project depend on it.

But, it does not mean that it is a very difficult process.

There is no rocket science to perform it because it is a very simple and easy process.

If you have full knowledge about the types of clamps, it will make it easier to understand the process.

But if you don’t know.

Don’t worry.

In this article, I will describe the importance of clamping, its types, requirements, and how to clamp large panels.

So, keep reading.

Importance of Proper Clamping Large Panels

Proper clamping is critical in woodworking, construction, and various DIY projects. Here are some important factors.

- Clamping enhances the structural integrity.

- Clamping prevents movement or misalignment, which can compromise the quality of the final product.

- Effective clamping distributes pressure evenly across the panel.

- Provides strong adhesion between surfaces to reduce the chances of gaps or weak joints.

- It helps to maintain proper alignment and smoothness, which is important for creating aesthetically pleasing and functional finished products.

- Increases the overall strength and longevity of woodworking and construction projects.

Types of Suitable Clamps for Large Panels

There are many types of clamps in the market, but three types are commonly used and considered suitable for effectively handling and securing large panels in woodworking or construction projects.

These are the main three types.

- Parallel Clamps

- Pipe Clamps

- Bar Clamps

1- Parallel Clamps

Parallel clamps are woodworking tools used to hold materials firmly in place during gluing, assembly, or other

operations.

They are available easily in the market in various sizes and consist of two jaws that move parallel to each other, which allows the uniform pressure to be distributed along the entire length of the workpiece.

Their simple design prevents warping or bending by evenly distributing pressure, ensuring a strong, square glue joint.

Parallel clamps are essential for precision woodworking projects to provide stability and accurate alignment.

2- Pipe Clamps

These types of clamps consist of a length of threaded pipe with movable jaws on each end. These jaws can be

adjusted along the pipe’s length to accommodate various workpiece sizes.

When you tighten the clamp, pressure is applied evenly, which holds pieces together for gluing or stabilization.

Pipe clamps are cost-effective, adaptable, and essential for projects requiring a strong and secure hold.

3- Bar Clamps

These clamps consist of a sliding jaw mechanism on a steel bar, allowing for adjustable clamping capacity to

suit different workpiece sizes.

When you turn a handle, the clamp applies pressure to secure the pieces firmly.

Bar clamps are versatile and provide a strong grip and even distribute pressure, which is crucial for precise woodworking projects and ensuring sturdy connections.

Necessary Tools and Accessories

A list of necessary tools and accessories is given below that will help you to perform the whole clamping process effectively.

- A large table or workbench

- Different clamps

- Drill

- Saw

- Clamping pads

- Hammer

- Screwdriver

- A Level

- Straight Edge

- Safety equipment (Gloves, Goggles, Hearing protection)

How to Clamp Large Panels Step-by-Step

Here’s a step-by-step guide, so follow all the steps.

- First of all, clear a flat surface to accommodate the large panels of plywood. Make sure that the panels are also clean and free of debris to prevent imperfections.

- Place the panels in the desired alignment, and make sure that the edges are flush and joints fit accurately.

- In large panels, it is crucial to apply the glue along the joint surface of panels to get the optimal results.

How to Clamp Large Panels So, apply glue evenly along all the edges.

- Lay the clamps across the panels’ width or length, depending on the project’s dimensions. Space the clamps evenly to ensure uniform pressure distribution.

- To prevent damage, place wooden blocks or pads between the clamp jaws and the panel’s surface.

- Align the clamps and gradually tighten them, then start from the center and work towards the edges. Alternatively, tighten the clamps to apply pressure evenly.

- Check the panel’s alignment and adjust the clamps if needed.

- Now wipe out the excessive glue from the panel joint with the help of a wet cloth.

- Don’t move the panels until the glue has fully dried. It takes time approximately 30-60 minutes.

- Once the glue has completely dried, carefully release the clamp pressure and remove the clamps from the panel assembly.

- Trim or sand any excess or uneven edges to achieve the desired finish for the project.

Note: By following these steps, you can effectively clamp large wood panels together, ensuring a strong and secure bond for your woodworking project.

Post-Clamping Considerations

Follow these simple steps for post-clamping considerations when working with large panels:

- Follow the manufacturer’s recommended drying time.

- After the recommended time, verify that the adhesive has fully cured.

- Gradually release clamping pressure from the panels in a sequential and controlled manner.

- Carefully examine the panel surfaces for any residual adhesive, imperfections, or irregularities.

Conclusion

The techniques, tools, and strategies discussed in this guide serve as invaluable resources for ensuring effective panel clamping.

By understanding the nuances of different clamp types, employing proper techniques, and observing post-clamping considerations, you can attain strong bonds and impeccable finishes in your projects.

Mastery of these clamping techniques not only enhances project outcomes but also elevates the craft and proficiency of woodworking and construction endeavors.

Thank you for your best time.

Best wishes