Learn: How Many Types of Plywood Exist in the Market

Plywood is a unique and widely used building material. It is not only strong and durable but also very cost-effective. Due to all these qualities, plywood has revolutionized the woodworking and construction industries.

It has different types for interior design, outdoors, furniture, and many other structural supports in construction.

So, Understanding the various types of plywood available is crucial for selecting the right material to achieve optimal results in any project.

I will explain the plywood types, grades, and uses in this article.

So, keep reading.

Understanding Plywood Grades

Plywood is available in different grades, indicating its quality and intended use. These grades range from A to D, with A being the highest quality with minimal blemishes and D being more suitable for structural purposes where appearance is not a primary concern.

Learn: How Many Types of Plywood Exist in the Market

Types of Plywood

Here, the market is full of different types of plywood. They are classified based on use, raw material, making process, and application in the required place.

Here, we will explain the most used types of plywood.

- Softwood Plywood

- Hardwood Plywood

- Tropical Plywood

- Aircraft Plywood

- Marine Plywood

- Structural Plywood

- Decorative Plywood

- Flexible Plywood

- Exterior Plywood

- Fire-Resistant Plywood

- Moisture-Resistant Plywood

- Overlaid Plywood

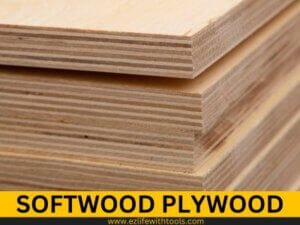

1- Softwood Plywood

It is a fundamental category of plywood manufactured from various species of coniferous trees, like pine, fir,

cedar, and spruce. It is recognized for its exceptional versatility.

It is manufactured from thin veneers sourced from softwood trees, with adjacent layers having their wood grain rotated at right angles to enhance the overall strength and stability of the panel.

Softwood plywood is very durable against the natural rule of wood to expand and contract due to changes in temperature and humidity.

Softwood plywood is very popular because it is very low-cost, lightweight, and easy to use, and it is available in different grades from A to D in the market.

Uses: We can use it in interior designs, furniture manufacturing, cabinets, DIY projects, temporary structures, educational projects, packaging, and architectural woodworking.

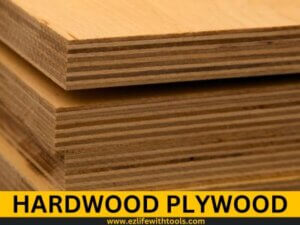

2- Hardwood Plywood

It is a highlighted type of plywood and is very popular due to its extraordinary strength, durability, and

aesthetic appeal.

The source of raw materials is denser and more robust trees like oak, maple, cherry, walnut, and birch because it increases the flexibility of plywood.

Hardwood plywood has the ability to bear heavy loads and resistance against wrapping and bending.

It is an ideal choice for high-quality visible surfaces because hardwood plywood has not only structural integrity but also offers aesthetic appeal.

Uses: We can use it in the manufacturing of flooring, wall paneling, doors, shelving, musical instruments, DIY/Hobby projects, marine projects, exhibitions, and film set designing.

3- Tropical Plywood

It is also known as tropical hardwood plywood and is manufactured from hardwood trees like mahogany, teak, meranti, and Okoume.

It can face challenging tropical climate pressure and also has exceptional durability, density, and resistance to decay and insects.

Tropical plywood manufacturing belongs to the Asian regions. And one positive thing is its low cost, due to its low costs, it’s mainly used in construction in huge quantity.

Uses: We can use it in the manufacturing of soundproofing, luxury interiors, marine and boating, docks, eco-friendly designs, flooring bases, high-quality furniture, and outdoor projects.

4- Aircraft Plywood

It is a specialized type of hard or thin birch plywood, and we can never neglect the importance of this crucial material in the aviation manufacturing and construction department. It was used during WWII to construct various aircraft.

Aircraft plywood is manufactured from birch wood, African mahogany, and poplar trees.

It is a lightweight, naturally sturdy and durable plywood and can bear high-stress loads, vibrations, and temperature fluctuations.

It plays a significant role in ensuring aircraft safety, performance, and reliability. These qualities make it an ideal choice to manufacture these critical aircraft components.

But it is a very expensive plywood due to the highest graded class.

Uses: We use aircraft plywood only to manufacture the Interior paneling, seating, flooring, instrument panels, wing structures, interiors, and bulkhead partitions of aircraft.

5- Marine Plywood

It is known as a specialized and essential material for the maritime and woodworking industries. It is also known as Boiling Water Proof Plywood (BWP).

Marine Ply can bear 72 hours of exposure to boiling water. Therefore, marine plywood is mainly used in boat building in places where exposure to water and humidity is constant.

This type of plywood is manufactured using a meticulous process that involves selecting high-quality hardwood veneers and bonding them with waterproof adhesives.

Marine plywood’s exceptional waterproofing properties are further ensured through exterior-grade glue, making it impervious to the delaminating effects of moisture and preventing fungal degradation even in humid and damp environments.

Uses: We use marine plywood in the manufacturing of saunas and steam rooms, soundproofing and acoustic panels, bathrooms and kitchen appliances, outdoor furniture, dock and pier construction, and boat and yacht construction.

6- Structural Plywood

Structural plywood plays a fundamental role in the construction industry as a robust and versatile building material. It consists of multiple layers of wood veneers bonded together with strong adhesives to provide stability.

This type of plywood is manufactured with strict adherence to stable grading and quality control standards. Therefore, its cross-laminated construction prevents the material from easily splitting or warping.

It is a very affordable plywood because it belongs to the C-grade class, but it does not mean that it is not suitable for outdoor work. It works according to its value.

Uses: Structural plywood is commonly used in outdoor construction projects and many other applications like sheathing, flooring, DIY projects, soundproofing, decorative paneling, structural columns and beams, temporary structures, packaging, exterior cladding, and formwork.

7- Decorative Plywood

It is a versatile and beautiful building material that has become very popular in interior design due to its

attraction. It is typically designed by bonding several layers of thin veneer sheets together. The outer layer is known as the face of plywood.

Oak, maple, cherry, teak, and mahogany trees wood used in the manufacturing of decorative plywood.

The interior work in any building can only be completed by installing decorative plywood.

Uses: We can use decorative plywood to construct theatres and entertainment spaces, home renovation, exhibition and trade show booths, office interiors, retail displays, ceilings, wall paneling, doors, and furniture.

8- Flexible Plywood

The name represents its characteristics. It is manufactured to complete those projects where a rigid plywood has failed to achieve the required shape or results.

Flexible plywood is very popular, also known as bendable or flexible panel, because it is specially designed for making curved parts of any furniture and application.

Normally, it is available in the market at a standard size of 1/8 inch or 3/8-inch thickness instead of 1/2 inch.

In the UK, it is famous for the name of hatter’s ply because it was once used in making stove-pipe hats during the Victorian era.

Uses: It is often used in the construction of curved surfaces, arts and crafts, model making, automotive interiors, boat buildings, architectural designs, exhibition stands, retail fixtures, and DIY projects.

9- Exterior Plywood

The name of this plywood shows that it is designed especially for outdoor uses and exposure to the elements. Then Definitely, the weather like rain, heat, and air storms will affect it.

Therefore, it is designed to bear the challenges posed by moisture, rain, temperature fluctuations, and sunlight, making it an essential building material for various outdoor construction projects.

It is very sturdy, durable and long-lasting plywood because it is made of several glued veneers.

It is known as a category of multi-ply plywood.

Its ability to bear harsh weather conditions while maintaining structural integrity makes it a reliable choice for projects where standard plywood or other materials would quickly deteriorate.

Uses: We can use it to construct exterior stairs, trailers, playground equipment, boat building, fencing, siding, decking, outdoor structures, and garden beds.

10- Fire-Resistant Plywood

It is a special plywood that looks the same as normal plywood. A beginner can never understand the difference between them.

Because the only thing that differentiates it from others is a special fire-retardant chemical (Diammonium hydrogen phosphate) used in the manufacturing process of fire-resistant plywood.

This chemical process increases the fire-resistance ability of plywood.

This plywood is also known by the name of FR-grade plywood.

The main purpose of this chemical is to increase the burning time. This chemical resists the penetration of flame into the fibers of plywood for a maximum of 20-30 minutes.

Uses: Fire-resistant plywood is mainly used in public places for construction work like large restaurants, train compartments, public theatres, halls, auditoriums, offices, heat ventilation ducts, and elevators.

11- Moisture-Resistant Plywood

This plywood is specially designed to bear the exposure to moisture, humidity, and damp conditions without structural degradation.

It is typically manufactured using exterior-grade adhesive resins and veneers treated with water-repellent chemicals.

Commonly, we know it as an MR plywood.

Moisture-resistant plywood helps prevent warping, delamination, and fungal decay, making it a reliable choice for environments where conventional plywood might deteriorate due to water absorption.

Therefore, it has become a popular choice of building material for interior and exterior use.

Uses: It is commonly used in applications with a risk of exposure to moisture, like bathrooms, kitchens, outdoor construction projects, ceiling panels, boat building, signage, and areas with high humidity levels.

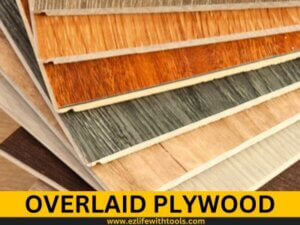

12- Overlaid Plywood

This type of plywood is manufactured from the wood of oak, ash maple, birch, mahogany, teak, rosewood, or

other hardwoods.

After this, a special protective layer will be applied on one or both sides of the panel, which differentiates it from others and is called overlaid plywood.

The main purpose of this layer is to enhance the plywood’s performance characteristics and provide a smooth, consistent, and hard-wearing surface.

This overlay can be made of durable material like phenolic resin-impregnated paper, melamine, or high-density polyethylene bonded to the plywood core under high pressure and heat.

The overlay not only protects the plywood from wear and tear but also makes it easy to clean and maintain.

Uses: This versatile overlay plywood is specially used to construct stage platforms, dance floors, countertops, exhibition booths, playground equipment, concrete formwork, and boat building.

Advantages and Disadvantages of Using Plywood

Advantages

- Plywood offers several benefits, including:

- Minimum material wastage.

- Cost-effectiveness compared to solid wood.

- High strength and durability.

- Resistance to shrinking and warping.

- Environmentally friendly manufacturing process.

- Available in different sizes and thicknesses.

Disadvantages

- Final finishing required, like paint and polish.

- Plywood quality assessment is difficult.

- Sealing or Edge banding is a must to protect them from mold damage and many other faults.

Conclusion

Plywood is a versatile building material available in various types and grades. Each type is designed to fulfil specific needs according to the specifications.

In the above-given article, I have explained all popular types of plywood with their usage and specifications with their advantages and disadvantages.

But it depends on your choice of which plywood you will select for your project. By choosing the right type of plywood, beginners and professionals can achieve their desired results efficiently and effectively.

Thank you for your time.

Best wishes

Frequently Asked Questions

Is plywood stronger than solid wood?

Yes, plywood is stronger than solid wood and creates resistance against warping due to their layered construction with alternating grain directions.

Can I use exterior plywood indoors?

While you can use exterior plywood indoors, it’s not always necessary. Always choose the plywood according to the specific needs.

What is marine plywood’s unique feature?

Marine plywood is specially designed to resist moisture, Which make it suitable for water-related applications.

Is plywood fireproof?

No, plywood is not fireproof. But a special type of fire-resistant plywood is available in the market, and always remember that it’s not also entirely fireproof.

Can I paint or stain plywood?

Yes. You can paint or stain the plywood, but it is necessary to prepare some essential steps for satisfactory finish.