How to Use a Coping Sled on a Router Table: Expert Tips

If you have planned a project that has small and irregular cutting of workpieces. Then definitely you can face

difficulties without the use of coping sled.

If you are a beginner, there is a big possibility that you don’t know about the use of coping sled and even its name.

So, in this article we will explain its anatomy, types, advantages and procedure that how to use a coping sled on a router table.

So, keep reading.

What is a Coping Sled?

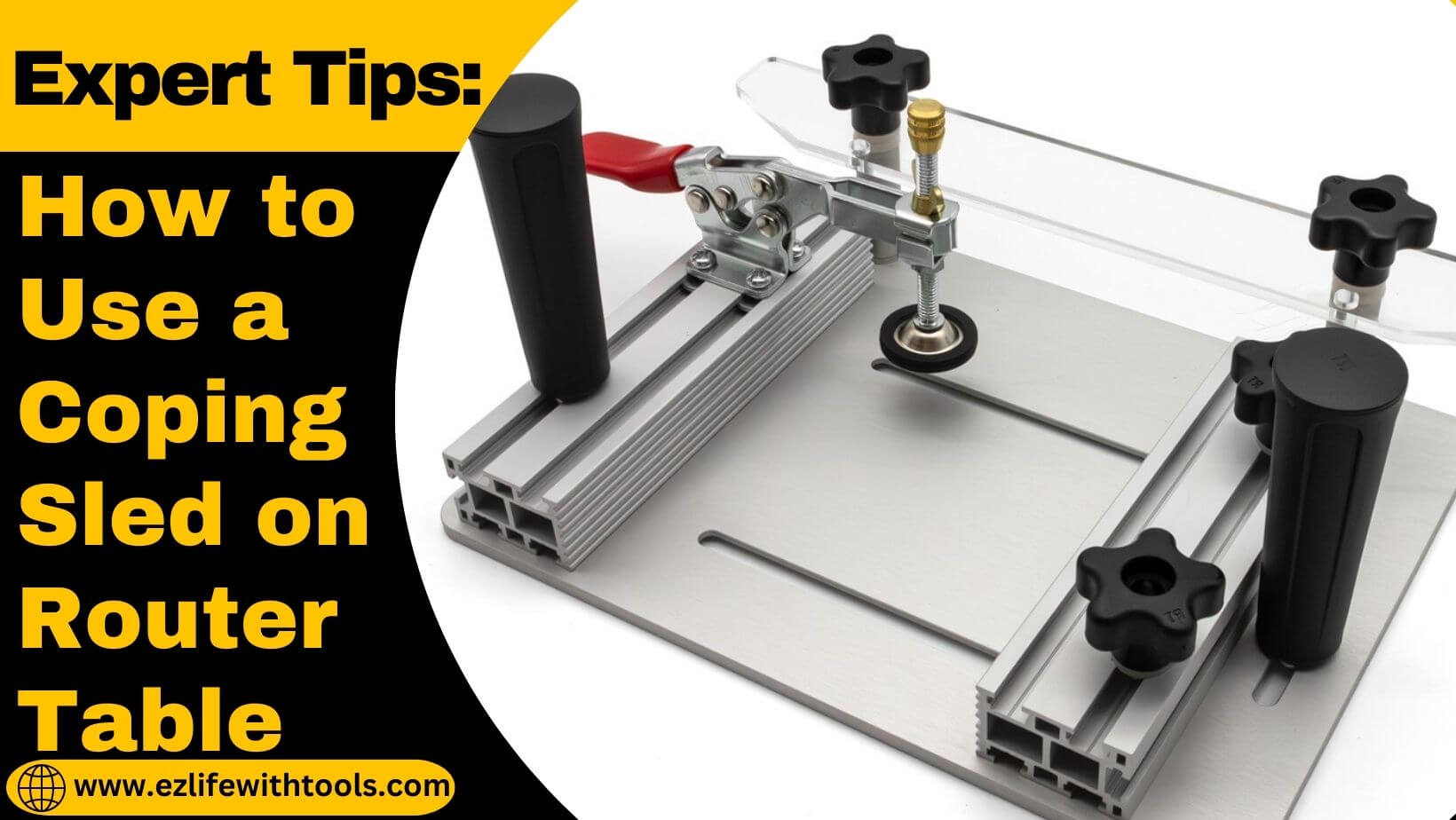

A coping sled is a specialized woodworking tool that is designed to be used in conjunction with a router table. The sled consists of a flat base with adjustable fences or clamps that help to hold the workpiece firmly and keep it in place. Its primary function is to hold and guide the workpiece securely during the routing process.

This simple tool is very useful to make a cope-and-stick joint, which is commonly used in making frames, cabinet doors, and other similar structures.

Parts of a Coping Sled

A typical coping sled consists of several main components:

- Base plate: This is the flat surface on which the workpiece rests. It is usually made of a solid material to provide stability and durability.

- Adjustable fences or clamps: These are the moving parts that secure the workpiece in place. The fence or clamp can be adjusted to accommodate different sizes and shapes of the workpiece.

- Handles or Knobs: Some coping sleds have handles or knobs that can be easily gripped and controlled by guiding the sled through the rotor table.

- Accessories or Attachments: We can also attach more additional accessories and attachments to improve the functions of the coping sled. These accessories, like dust collection ports and different guides for special kits, depend on the model you use for your project.

Types of a Coping Sled

Standard Coping Sleds: These sleds usually have a flat base with an adjustable fence or clamp and are suitable for general woodworking and cope-and-stick joinery.

- Specialized Coping Sleds

- DIY or Custom Coping Sleds

- Commercial Types Coping Sleds

1- Specialized Coping Sleds

These are sleds designed for specific applications or materials like small or unusual-shaped workpieces that require unique functionality.

2- DIY or Custom Coping Sleds

Woodworkers often build their own coping sleds to their specific needs using DIY plans or modifying existing sleds for particular projects.

3- Commercial Types

Manufacturers offer a range of competing sleds with different features, materials, and design aspects to meet different woodworking preferences and needs.

Note: All these types are designed to meet different woodworking needs, and artisans choose the most suitable sled based on their specific project needs and preferences.

Advantages of Using a Coping Sled for Woodworking

Woodworking, especially work that involves routers, demands accuracy, safety, and precision. Here’s why a competition sled is essential in this craft:

- Enhanced safety measures: Extreme safety is required when you work with power tools like a router. In this situation, coping sleds provide a safe and controlled environment for routing, reducing the risk of accidents or injuries caused by unstable workpieces.

- Precision and Accuracy: Woodworkers strive for precision in their cuts, especially when cutting joints, because a bit of change in cut can change the whole picture of your project.

- Coping sleds help achieve this accuracy by continuously guiding the workpiece through the router bit, resulting in precise cuts that fit together seamlessly.

- Finished Product Quality: Using coping sleds significantly improves the quality of woodworking projects by reducing splits. This tool makes sure that the final look of the product is professional and free from any imperfections caused by poorly supported workpieces.

- Versatility and Adaptability: There is no difference; coping sleds always offer versatility and adaptability, whether it’s making specific joints or handling a variety of workpieces. These qualities make the coping sled the favorite of every woodworker.

- Handling of small or irregularly shaped workpieces: Coping sleds are particularly useful for handling small or irregularly shaped workpieces that may be difficult to manage on a router table. The sled’s adjustable fences or clamps hold the pieces securely, allowing for stable and controlled routing operations.

How to Use a Coping Sled on a Router Table Step-by-Step

You can divide this whole process into four parts for better understanding.

- Preparation and Setup of Router Table

- Installing the Workpiece in the Cutting Sled

- Adjusting the Cutting Sled for the Desired Cut

- Operating the Router and Sled Safely

1- Preparation and Setup of Router Table

Before using the coping sled on the router table, proper setup and preparation are essential. Follow these simple steps to prepare the Router table.

- Make sure your router table is clean, stable, and securely positioned.

- Insert the appropriate router bit and adjust its height to the depth required for the cut.

- Set the fence and any guides on the router table to properly accommodate the coping sled and workpiece.

- Double-check all safety features, such as emergency stop buttons or dust collection systems, and make sure they are functional before starting any operation.

2- Installing the Workpiece in the Cutting Sled

Proper installation of the workpiece in the coping sled is critical to safe and accurate routing. Follow these simple steps for safe installation.

- Select the appropriate cutting sled type and size that fits your workpiece.

- Place the workpiece on the cutting sled and use a secure mechanism to hold it firmly in place.

- Make sure that your workpiece is level and firmly attached to the sled. It is the essential step to prevent any movement during the routing process.

3- Adjusting the Cutting Sled for the Desired Cut

Adjusting the sled ensures accuracy and precision of the routing operation:

- Align the fence or guides on the coping sled to ensure that they are parallel to the fence of the router table for consistent cuts.

- Set the depth and angle of the cutting sled according to the specific cut or joint you want to make.

- Perform a test run on scrap material to ensure the sled is correctly adjusted for the desired cut before working on the actual project.

4- Operating the Router and Sled Safely

Always focus on your primary safety when using a router table and coping with a sled:

- Please turn on the router and let it reach its full speed before engaging with the workpiece.

- Maintain a steady and controlled feed rate while guiding the sled through the router table to avoid sudden movement or shock.

- After the completion of the routing process, turn off the router and allow the bit to come to a complete stop before removing the workpiece from the sled.

Common Mistakes When Using a Coping Sledge on a Router Table

Not securing the Workpiece Properly:

- If you have failed to properly secure the workpiece in the cutting sled, it will lead you to unexpected shifting or movement of the workpiece during the routing process.

- An unsecured workpiece can slip or move, which will potentially cause accidents, injury to the woodworker, or damage to the project.

- An unsecured workpiece can cause inconsistent cuts or joints, which can affect the accuracy and quality of a woodworking project.

Use of Improper Settings or Adjustments:

- Improper adjustments on the cutting sled, such as incorrect depth settings or incorrectly installed fences, can result in incorrect cuts or poor joints.

- Improper settings can damage the quality and professional look of the workpiece.

- Improper adjustments can damage and waste your costly wood piece, which will lead you towards the rework or possibly project failure.

Ignoring Safety Precautions:

- Ignoring safety precautions when using a cutting sled on a router table can lead to accidents or serious injuries.

- Neglecting to wear protective goggles, mask, and other gear when working in flying debris, moving parts, and in the presence of loud noise.

Conclusion

Mastering the use of a coping sled on a router table is an essential skill for any woodworker. This specialized tool not only ensures safety and accuracy but also improves the overall quality of woodworking projects.

Properly securing the workpiece inside the sled, making correct adjustments, and adhering strictly to safety measures are essential practices to achieve successful and efficient routing.

I have done my responsibility to describe all the guidelines in this article; if you follow them, you will be able to use the coping sled on the router table securely.

Now go and do it with confidence.

Thank you for your time.

Best wishes